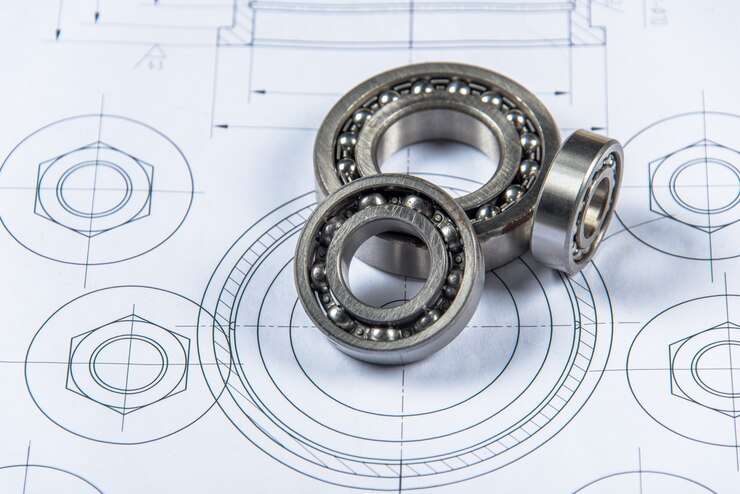

Bearings are fundamental mechanical components that reduce friction and enable smooth motion between moving parts. They are indispensable in virtually every industry, ensuring efficiency, precision, and long-term operation of machinery and systems. In this article, we explore the major types of bearings and their specific applications in various industries.

1. Automotive Industry

The automotive sector heavily relies on bearings for efficient vehicle operation, from everyday passenger cars to heavy-duty trucks. Common types of bearings used include:

- Ball Bearings: Found in wheel hubs, alternators, and air conditioning systems, they handle both radial and axial loads.

- Tapered Roller Bearings: Essential for wheel applications and steering, these bearings manage heavy loads and withstand high stresses.

- Needle Bearings: Frequently used in transmission systems, these compact bearings handle high-speed rotation in tight spaces.

Bearings enhance fuel efficiency, reduce noise, and improve vehicle safety by ensuring consistent performance and reducing friction.

2. Aerospace Industry

In aerospace, precision and reliability are non-negotiable. Bearings used in aircraft must withstand extreme temperatures, high speeds, and harsh conditions:

- Spherical Bearings: Used in control systems and landing gear assemblies for their ability to tolerate misalignment.

- Ceramic Bearings: Preferred for their lightweight and corrosion-resistant properties, ideal for high-speed applications in jet engines and turbines.

Aerospace bearings are meticulously designed and tested to meet rigorous standards for durability and safety.

3. Industrial Machinery

Bearings play a pivotal role in industrial machinery, where they support rotating shafts, facilitate load transfer, and minimize friction:

- Roller Bearings: Used in conveyor systems, electric motors, and presses due to their capacity to handle heavy radial loads.

- Thrust Bearings: Essential for supporting axial loads in machinery like compressors and pumps.

- Plain Bearings: Common in heavy machinery due to their ability to accommodate large loads without complex components.

The smooth operation of factories and production lines depends on the reliable performance of these bearings, reducing downtime and enhancing productivity.

4. Energy Sector

The energy industry, including wind power, hydroelectricity, and thermal plants, depends on specialized bearings to optimize output:

- Wind Turbine Bearings: Large slewing ring bearings support the turbine’s rotational movement, while main shaft bearings ensure smooth blade rotation.

- Hydro Bearings: Custom-designed for turbines in hydroelectric power plants, these bearings handle high loads and water exposure.

- Magnetic Bearings: Used in compressors and high-speed rotational systems due to their frictionless operation and minimal wear.

In renewable energy applications, high-performance bearings enhance efficiency and extend equipment life.

5. Electronics and Electrical Appliances

Bearings in electronics and household appliances are critical for noise reduction and efficient operation:

- Miniature Bearings: Found in computer fans, hard drives, and precision instruments, these small bearings provide accurate rotation at high speeds.

- Ball Bearings: Common in washing machines, vacuum cleaners, and fans, they reduce friction and enhance motor efficiency.

Manufacturers emphasize compact designs and high performance to meet consumer demands for quieter, longer-lasting devices.

6. Railways and Transportation

Railway systems depend on bearings for safe and efficient transport:

- Spherical Roller Bearings: Used in axle boxes and traction motors for heavy-duty applications with high load capacity.

- Tapered Roller Bearings: Ensuring the stability and smooth motion of train wheels, these bearings handle both radial and axial forces.

Bearings contribute to safety, reduce energy consumption, and lower maintenance costs in railway networks.

7. Food and Beverage Industry

The food and beverage industry demands high standards of hygiene and reliability:

- Stainless Steel Bearings: Resistant to corrosion and contamination, used in food processing equipment, mixers, and conveyors.

- Sealed Bearings: Prevent contamination from dust and liquids, crucial for maintaining safety and compliance.

Bearings ensure smooth production and meet stringent health standards.

8. Construction and Heavy Equipment

Bearings in construction equipment, such as excavators, cranes, and bulldozers, are designed to endure tough conditions:

- Slewing Bearings: Found in rotating platforms of cranes and excavators, these bearings support heavy loads and rotational motion.

- Self-Aligning Bearings: Essential for construction machinery that operates on uneven terrain, accommodating misalignments and heavy shocks.

Durability and load capacity are critical factors for bearings in this sector.

Conclusion

Bearings serve as essential components in nearly every industry, tailored to meet specific operational demands and environmental conditions. Their unique designs and advanced materials ensure smooth operation, efficiency, and reliability in countless applications. As industries evolve, bearings will continue to play a vital role in driving technological progress and operational excellence.